WDR and SNAP RING pressing - CPS21

The machine is designed for pressing WDR and snap rings into the pump flange.

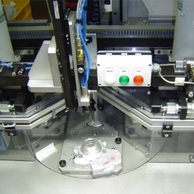

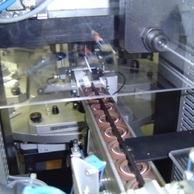

The device works on the principle of a semi-automatic workplace with a turntable with four working positions. The operator performs manual loading. In the subsequent automatic process, the loaded flange body is inspected, lubricated with oil mist and subsequently moved by turning the table to the next working position. In other working positions, controlled pressing of sealing rings and washers by PROMESS units is performed. The device comes with a set of 9 loading sets. The machine is ready to expand up to 60 sets of loading nests.

The control system of the CPS21 machine is built on a PC platform. Thanks to this, the device has an above-standard implementation of diagnostic and visualization functions such as photographic previews, remote management, process parameterization via Ethernet, the possibility of adding other type sets via a dialog panel or remote access.

Photo gallery